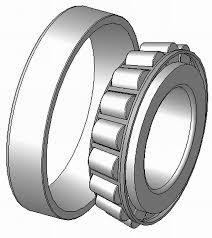

Cylindrical Roller Bearings Crushers Industries

Product Details:

- Thickness Up to 60 mm

- Cage Material Brass/Steel

- Retainer Yes

- Lubrication Type Grease/Oil

- Inside Diameter Up to 260 mm

- Precision Rating P0, P6, P5

- Bearing Type Cylindrical

- Click to View more

Cylindrical Roller Bearings Crushers Industries Price And Quantity

Cylindrical Roller Bearings Crushers Industries Product Specifications

- High

- Up to 260 mm

- Grease/Oil

- Yes

- Brass/Steel

- Up to 60 mm

- Customizable

- Open/Sealed

- P0, P6, P5

- Cylindrical Roller Bearing

- Cylindrical

- Up to 5200 RPM

- Chrome Steel (GCr15)

- Up to 320 mm

- Single Row

Cylindrical Roller Bearings Crushers Industries Trade Information

- 10000 , Per Week

- 3 Days

Product Description

URB Cylindrical Roller Bearings For Crushers Industries

Available in different sizes, offered Cylindrical Roller Bearings Crushers Industries are used as integral parts of pumps and gearboxes. Featured with single row based design, offered roller bearings are extensively used in cement manufacturing, agricultural, heavy machine production and also in other industries. Cylindrical Roller Bearings Crushers can endure heavy load and shock load. Moreover, these roller bearings are capable of withstanding vibration. These low maintenance bearings for crusher industry can be used in dust prone working environment. Perfect diameter and smooth rotation are the key aspects of these bearings.

Engineered for Extreme Conditions

Cylindrical Roller Bearings for crushers and mining are engineered to withstand harsh operating environments. Their high load capacity, robust Chrome Steel (GCr15) material, and heat-treated surfaces ensure reliability even in fluctuating temperatures and heavy loads. Precision ground finishes reduce wear, improving lifecycle and maintaining high performance in demanding industries.

Versatile and Customizable

These bearings are available in a range of sizes, sealing types, and mounting options, making them adaptable to various application requirements. From single-row bearings with customizable bore sizes to open and sealed formats, users can choose specifications that best suit their crushers or mining equipment. The modular design supports press fit or slip fit mounting, ensuring integration with different machinery setups.

FAQs of Cylindrical Roller Bearings Crushers Industries:

Q: How are cylindrical roller bearings used in crusher and mining industries?

A: Cylindrical roller bearings support moving parts in crushers and heavy mining machinery, ensuring smooth operation by handling high radial loads and withstanding severe working conditions. Their design helps reduce friction and enhances the overall efficiency of crushing equipment.Q: What benefits do heat-treated, precision-ground bearings offer for heavy industry applications?

A: Heat-treated, precision-ground bearings deliver increased durability, improved load-bearing capacity, and resistance to wear. This results in longer operational life and reduced maintenance needs for equipment operating in demanding settings such as mining and crushing.Q: When should open versus sealed cylindrical roller bearings be selected?

A: Open bearings are chosen for environments where regular maintenance and lubrication are feasible, while sealed bearings are preferred in dusty, wet, or contaminated settings, as they protect against debris and maintain lubrication, extending bearing life.Q: Where can these cylindrical roller bearings be applied apart from crushers?

A: Beyond crusher equipment, these bearings are widely used in other heavy industry sectors such as mining conveyor systems, material handling, and machinery that requires robust load-bearing components.Q: What is the process for mounting these bearings in industrial equipment?

A: The bearings are typically mounted using either press fit or slip fit methods, depending on equipment design. Proper installation requires clean surfaces and compatible tools to ensure optimal alignment, secure fit, and reliable operation.Q: What advantages does Chrome Steel (GCr15) provide for bearing durability and performance?

A: Chrome Steel (GCr15) offers excellent hardness, strength, and resistance to wear and corrosion. This material ensures the bearings maintain their integrity and functionality, even under high stress and variable temperature conditions experienced in heavy industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'URB Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free