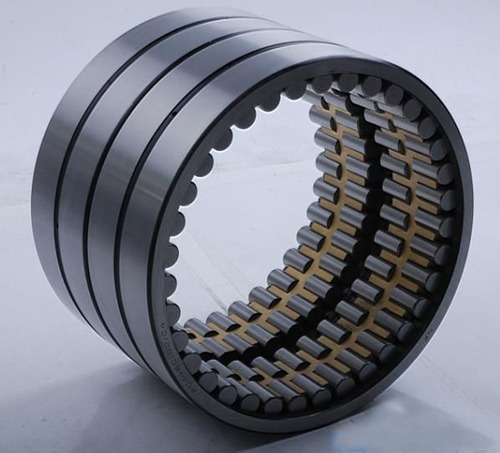

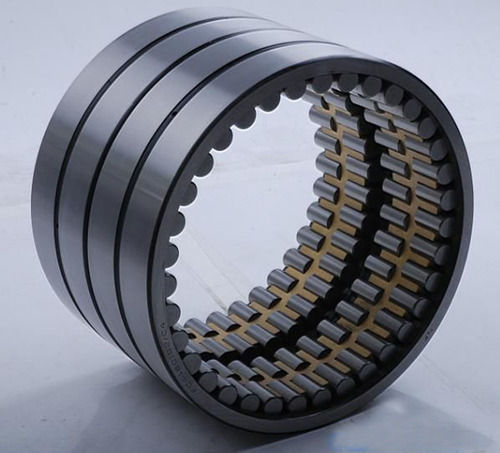

URB Cylindrical Roller Bearings For Rolling Mills

Product Details:

- Thickness Standard/Custom

- Weight Depends on Size & Series

- Material Chrome Steel

- Ball Bearing Type Cylindrical Roller Bearing

- Roller Bearing Type Single Row, Double Row, Four Row

- Structure Cylindrical

- Seals Type Open/Sealed

- Click to View more

X

URB Cylindrical Roller Bearings For Rolling Mills Price And Quantity

- 10000 Piece

URB Cylindrical Roller Bearings For Rolling Mills Product Specifications

- Up to Four Rows

- Open/Sealed

- Depends on Size & Series

- 400-4500 RPM

- As per order/specification

- Chrome Steel

- Standard/Custom

- Single Row, Double Row, Four Row

- High Load Capacity (Application Specific)

- Cylindrical

- Cylindrical Roller Bearing

- As per order/specification

- Up to 1300 mm

URB Cylindrical Roller Bearings For Rolling Mills Trade Information

- 10000 Piece Per Day

- 3 Days

Product Description

URB Cylindrical Roller Bearings for Rolling Mills are a popular and highly customizable solution for the challenging environments of rolling mills across India. Engineered for dazzling performance and grand durability, these imposing bearings feature precision ratings of P5 and P6, supporting both grease and oil lubrication options. Constructed from premium chrome steel with robust brass cages, they handle high loads and demanding applications with ease. Available in single, double, or four-row structures, with bore sizes up to 1300mm, you can pick yours to fit any specificationensuring optimal efficiency and reliability for your machinery.

Trusted in Rigorous Rolling Mill Applications

URB Cylindrical Roller Bearings For Rolling Mills are widely used by steel manufacturers, heavy industry operators, and mechanical engineers. With their impressive application surface, these bearings are tailored for high-frequency, large-scale rolling processes. Their advanced usage type accommodates everything from precision rolling to continuous, demanding mill environments, maintaining performance and durability over extended use. Designed for prolonged operational cycles, they remain integral in industries where efficiency and resilience are non-negotiable.

Strategic Export & Supply for Global Reach

URB Cylindrical Roller Bearings For Rolling Mills are shipped from major FOB ports in India, ensuring smooth transportation to your destination. Our main export markets include Asia, Europe, and Africa, with an expansive supply network covering diverse industrial segments. Sample availability lets clients evaluate specifications before bulk expenditure. Our logistical process prioritizes timely delivery and efficient handling, minimizing transport costs and ensuring that bearings arrive in top condition, ready for immediate installation in your rolling mills.

Trusted in Rigorous Rolling Mill Applications

URB Cylindrical Roller Bearings For Rolling Mills are widely used by steel manufacturers, heavy industry operators, and mechanical engineers. With their impressive application surface, these bearings are tailored for high-frequency, large-scale rolling processes. Their advanced usage type accommodates everything from precision rolling to continuous, demanding mill environments, maintaining performance and durability over extended use. Designed for prolonged operational cycles, they remain integral in industries where efficiency and resilience are non-negotiable.

Strategic Export & Supply for Global Reach

URB Cylindrical Roller Bearings For Rolling Mills are shipped from major FOB ports in India, ensuring smooth transportation to your destination. Our main export markets include Asia, Europe, and Africa, with an expansive supply network covering diverse industrial segments. Sample availability lets clients evaluate specifications before bulk expenditure. Our logistical process prioritizes timely delivery and efficient handling, minimizing transport costs and ensuring that bearings arrive in top condition, ready for immediate installation in your rolling mills.

FAQs of URB Cylindrical Roller Bearings For Rolling Mills:

Q: How are URB Cylindrical Roller Bearings customized to suit rolling mill requirements?

A: URB cylindrical roller bearings are available in various configurations, such as single, double, or four-row structures, and can be produced with specific bore and outside diameters as per order. This allows end-users to select bearings tailored precisely to their machinerys technical demands and operational load.Q: What is the primary benefit of using brass cage cylindrical roller bearings in rolling mills?

A: Brass cages offer remarkable strength and heat resistance, ensuring the bearings maintain their structure and reliability under intense mechanical and thermal stresscommon in rolling mills. This construction provides excellent durability and prolongs bearing life in rigorous industrial environments.Q: Where are URB Cylindrical Roller Bearings typically installed?

A: These bearings are widely installed in rolling mills used in steel and metal processing plants, where high-load, high-temperature, and high-speed operations are routine.Q: When should I choose a four-row cylindrical roller bearing?

A: Four-row bearings are best selected when high radial loads and limited axial space are present. They provide robust load capacity, making them suitable for demanding rolling mill applications with heavy and continuous operation.Q: What is the process for ordering a customized bearing with specific dimensions?

A: Clients can submit their design specifications (such as inner and outside diameters, number of rows, and thickness) to the distributor or supplier. After technical review, the bearing is manufactured as per order, ensuring a precise fit for the intended application.Q: How does the availability of both grease and oil lubrication add value?

A: Offering both grease and oil lubrication options allows users to match their maintenance schedules and operating temperatures, enhancing bearing performance and reliability for various rolling mill processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'URB Bearing For Rolling Mills' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |