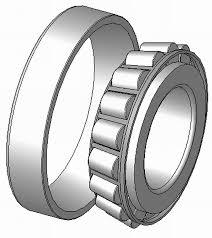

URB Taper Roller Bearings

200.00 - 2000.00 INR/Piece

Product Details:

- Precision Rating P0, P6, P5

- Lubrication Type Other

- Retainer Steel

- Inside Diameter 90 mm

- Cage Material Steel

- Thickness 43 mm

- Bearing Type Tapered Roller Bearing

- Click to View more

X

URB Taper Roller Bearings Price And Quantity

- 200.00 - 2000.00 INR/Piece

- 50 Piece

URB Taper Roller Bearings Product Specifications

- Steel

- 190 mm

- 90 mm

- 43 mm

- Steel

- 3200 rpm

- 90 mm

- High

- P0, P6, P5

- Single Row

- Other

- Other

- Taper Roller

- Tapered Roller Bearing

- Open

URB Taper Roller Bearings Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 10000 Piece Per Week

- 3 Days

- All India

Product Description

Endowed with in-depth industry experience, we are engaged in providing the best quality array of URB Tapered Roller Bearings to our valued clients. At our reputed vendors end, these bearings are manufactured using premium grade metal alloys and sophisticated techniques. Suitable to be used in paper mills, stone crushing units, cranes and lifting tackles, the offered bearings are known for their excellent dimensional stability. Besides, our patrons can purchase these URB Tapered Roller Bearings at economical prices from us.

Features:

Features:

- Finely grooved

- High durability

- Compact size

- Easy to install

High Load Capacity for Demanding Applications

URB Taper Roller Bearings are tailored for high-load environments, with dynamic and static load ratings of 280 kN and 330 kN, respectively. Their design ensures superior performance and reliability across automotive, gearbox, and industrial machinery sectors, making them ideal for use in heavy-duty scenarios.

Precision Engineering for Enhanced Performance

Manufactured with high-precision ratings (P0, P6, P5), these bearings feature a single-row tapered structure for optimal alignment and reduced friction. The steel cage and retainer contribute to extended durability and stability, ensuring the bearings operate efficiently under diverse conditions.

Wide Operating Temperature and Speed Range

Capable of withstanding temperatures from -30C to +120C and reaching limiting speeds up to 3200 rpm, these bearings are suitable for various industrial environments. The open-seal design enables effective lubrication management and supports longevity with minimal maintenance requirements.

FAQs of URB Taper Roller Bearings:

Q: How should URB Taper Roller Bearings be installed for optimal performance?

A: URB Taper Roller Bearings require proper alignment and careful mounting to ensure they perform at their best. It is important to use the correct tools, apply the recommended lubricant, and avoid applying excessive force during installation. Following the manufacturers guidelines will help maximize the bearings operational life.Q: What applications are best suited for these bearings?

A: These bearings excel in automotive systems, gearboxes, and a range of industrial machinery where high dynamic and static load capacities are critical. Their robust construction and precision ratings make them ideal for heavy-duty and high-speed operations.Q: When should these bearings be replaced or inspected?

A: Regular inspection is recommended, especially if the machinery is exposed to high loads or operates continuously. Bearings should be checked for wear, unusual noise, temperature changes, and lubricant condition during scheduled maintenance intervals as specified by equipment manufacturers.Q: Where can I purchase URB Taper Roller Bearings in India?

A: URB Taper Roller Bearings are widely available across India through authorized distributors, importers, suppliers, and wholesalers. You can contact local suppliers or visit their official distribution partners for genuine products and technical support.Q: What is the process for selecting the right bearing for my application?

A: To select the appropriate URB Taper Roller Bearing, consider load requirements, operating temperature, speed, bore size, and precision rating. Consulting the product datasheet and collaborating with technical experts or distributors can help ensure the chosen bearing matches your specific application needs.Q: How does the open seal design benefit industrial machinery?

A: The open seal design allows for efficient heat dissipation and facilitates easy relubrication. This structure is advantageous in applications where frequent maintenance is possible and optimal lubrication is essential for prolonged bearing life.Q: What are the primary benefits of using URB Taper Roller Bearings?

A: These bearings provide high load capacity, reliable performance at a broad temperature range, precision engineering, and robust construction. Their adaptability to various demanding environments and ease of maintenance contribute to reduced downtime and enhanced machinery efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'URB Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free