URB Thrust Bearings

Product Details:

- Thickness Vary as per model (e.g., 5 mm to 40 mm)

- Inside Diameter Varies as per model

- Cage Material Brass / Steel

- Lubrication Type Other

- Retainer Pressed Steel

- Precision Rating P0, P5 (based on model)

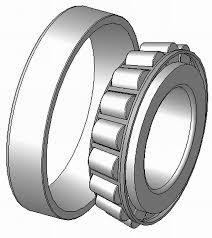

- Bearing Type Thrust Ball Bearing

- Click to View more

X

URB Thrust Bearings Price And Quantity

- 50 Piece

URB Thrust Bearings Product Specifications

- Other

- Vary as per model (e.g., 5 mm to 40 mm)

- Thrust

- Brass / Steel

- Thrust Ball Bearing

- Varies as per model (e.g., 20 mm to 300 mm)

- Varies as per model

- High axial load capacity (exact value depends on size)

- Vary as per model (e.g., 10 mm to 200 mm)

- Other

- Single and Double (as per model)

- Open

- 3000-15000 RPM (depends on bearing size and design)

- P0, P5 (based on model)

- Pressed Steel

URB Thrust Bearings Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- 10000 Piece Per Week

- 3 Days

- All India

Product Description

We are providing URB thrust bearings that are provided with two options: with flat seats and with aligning seats. The choice of bearings depends on the shape of the housing washer, which is also known as the outer ring seat. Key feature of these thrust bearings is that they can corroborate all types of axial loads, but the same is not true for radial loads. The URB thrust bearings are made using ultra clean steel, which is instrumental in increasing the bearing life.

Versatility Across Industries

URB Thrust Bearings are designed to meet the rigorous demands of automotive, machinery, industrial, and electric motor applications. Their adaptability in structure and sizing makes them a preferred choice for distributors, suppliers, and importers throughout India seeking reliable thrust bearing solutions.

Superior Engineering & Reliability

Each URB Thrust Bearing adheres to ISO standards and boasts a polished, corrosion-resistant finish. High load capacity, precision ratings (P0, P5), and material quality ensure dependable performance, whether used in high-speed motors or heavy-duty machinery.

Installation & Maintenance Made Simple

Thanks to their standardized dimensions and open-seal design, these thrust bearings are straightforward to install and maintain. The availability in various bore sizes and rows streamlines replacement processes and supports efficient operation in critical systems.

FAQs of URB Thrust Bearings:

Q: How do I select the appropriate URB Thrust Bearing model for my application?

A: Choosing the correct model depends on your applications axial load requirements, shaft diameter (bore size ranges from 10 mm to 200 mm), and installation space. Its important to check the limiting speed and compatibility with your equipments typewhether automotive, industrial, or electric motors.Q: What benefits do URB Thrust Bearings offer for industrial machinery and automotive use?

A: These bearings deliver reliable axial load handling, high durability, and corrosion resistance suitable for tough operating conditions. Their polished surface and ISO-certified construction ensure long service life and lower maintenance needs in both machinery and automotive environments.Q: When should I consider single versus double row URB Thrust Bearings?

A: Single row bearings are ideal when moderate axial loads are present, while double row models are better suited for higher axial loading requirements. Selection depends on your applications mechanical design and expected load conditions.Q: Where can URB Thrust Bearings be sourced in India?

A: They are available through authorized distributors, importers, wholesalers, and suppliers across India. Look for genuine URB-TSERIES products to ensure compliance with quality standards and reliable performance.Q: What is the process for installing URB Thrust Bearings?

A: Installation typically involves placing the bearing between the two mating surfaces that support axial load. Open seal designs facilitate easy handling and fitting. Check your equipments manual for specific installation tolerances and lubrication recommendations.Q: What are the usage limits regarding speed and load capacity for these bearings?

A: URB Thrust Bearings support high axial loads, with exact values dependent on the selected size and model. The limiting speed ranges from 3,000 to 15,000 RPM, varying by bearing diameter and type; always consult model-specific data for optimal performance.Q: What distinguishes URB Thrust Bearings in terms of durability and maintenance?

A: With precision ratings (P0, P5), polished corrosion-resistant finish, and robust brass or steel cage materials, these bearings stand out for their longevity. Their easy-to-install structure minimizes maintenance intervals, reducing downtime in critical systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'URB Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free