Commercial Turbine Bearings

Product Details:

- Cage Material Brass

- Thickness 11 mm

- Lubrication Type Grease Lubrication

- Inside Diameter 15 mm

- Precision Rating P6

- Retainer Available

- Bearing Type Turbine Bearing

- Click to View more

X

Commercial Turbine Bearings Price And Quantity

- 10000 Piece

Commercial Turbine Bearings Product Specifications

- 35 mm

- Double Sealed

- 15 mm

- Single Row

- 15 mm

- Available

- P6

- Turbine Bearing

- Spherical

- 11 mm

- High Load

- Brass

- 3600 RPM

- Chrome steel

- Grease Lubrication

Commercial Turbine Bearings Trade Information

- 10000 Piece Per Week

- 3 Days

Product Description

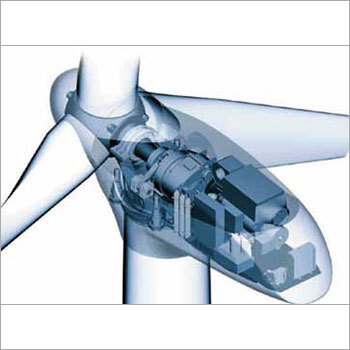

Our organization has attained a leading position in the market by supplying a broad gamut of Commercial Turbine Bearings. These bearings are mainly installed in turbines for reducing rotational friction and supporting axial loads. Under experienced professionals' observation, provided bearings are manufactured with the use of quality-tested metal alloys and highly advanced techniques. Apart from this, our valued patrons can get these Commercial Turbine Bearings from us in vivid dimensions at viable prices.

Features:

- Corrosion resistance

- Smooth edge

- Simple installation

- Precise dimension

Engineered for Durability and Efficiency

Our turbine bearings are designed to deliver outstanding performance in commercial turbine environments. With a high load capacity and resistance to corrosion, they reliably operate between -30C and 200C. Their double-sealed design keeps out contaminants, while the polished chrome steel surface provides minimal friction and wear. The robust brass cage and grease lubrication ensure smooth operation and extended lifespan, even at high speeds.

Precision Performance for Demanding Applications

Featuring a P6 precision rating, these bearings offer stable and efficient rotations, making them ideal for critical turbine machinery. The press-fit mounting simplifies installation, and the spherical structure manages alignment, reducing maintenance. Each bearing is boxed for protection and supplied by trusted distributors, importers, and suppliers nationwide, assuring quality and rapid availability across India.

FAQs of Commercial Turbine Bearings:

Q: How are commercial turbine bearings used in turbine applications?

A: Commercial turbine bearings support the rotating components within turbines, providing stability, reducing friction, and ensuring smooth and efficient operation under high loads and variable temperatures.Q: What are the benefits of the double-sealed design in these bearings?

A: The double-sealed design protects the bearings internal components from dust, moisture, and contaminants, enhancing durability and prolonging service life, even in harsh turbine environments.Q: When should I consider replacing a commercial turbine bearing?

A: Bearings should be replaced if you notice increased vibration, noise, reduced performance, or signs of wear and corrosion. Regular maintenance checks help detect these issues early to prevent unplanned downtime.Q: Where can I purchase these commercial turbine bearings in India?

A: These bearings are available from authorized distributors, importers, suppliers, and wholesalers throughout India, ensuring convenient procurement for both large and small-scale commercial projects.Q: What is the installation process for these turbine bearings?

A: Installation involves press-fitting the bearing into the housing, ensuring proper alignment to maximize performance. Its important to follow manufacturer guidelines for mounting and lubrication to achieve optimal results.Q: How does the spherical structure benefit turbine machinery?

A: A spherical bearing structure allows for some misalignment between shaft and housing, reducing operational stress and ensuring consistent load distribution, which is especially beneficial in dynamic turbine environments.Q: What advantages does grease lubrication provide for these bearings?

A: Grease lubrication minimizes friction, protects against rust and corrosion, and supports smooth operation over a wide temperature range, extending bearing life and reducing maintenance requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |