Bearings for Mining Industry

Product Details:

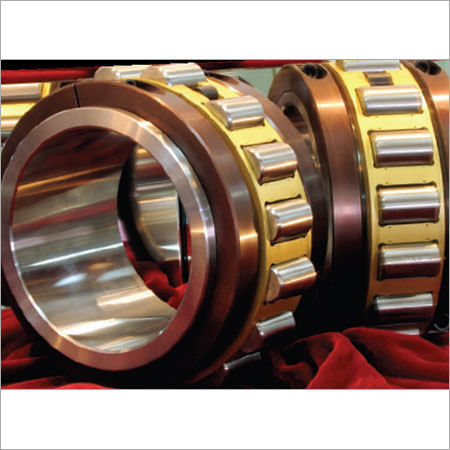

- Inside Diameter 30 mm to 300 mm

- Cage Material Steel/Brass/Polyamide

- Thickness 18 mm to 80 mm

- Lubrication Type Grease/Oil

- Retainer Steel/Brass

- Precision Rating ABEC 1 to ABEC 5

- Bearing Type Ball/Spherical Roller/Tapered Roller

- Click to View more

X

Bearings for Mining Industry Price And Quantity

Bearings for Mining Industry Product Specifications

- 30 mm to 300 mm

- Up to 1000 kN

- Chrome Steel / Stainless Steel

- Single or Double

- 60 mm to 400 mm

- 30 mm to 300 mm

- Ball/Spherical Roller/Tapered Roller

- Grease/Oil

- Steel/Brass

- Steel/Brass/Polyamide

- 1000 to 6000 RPM

- 18 mm to 80 mm

- ABEC 1 to ABEC 5

- Deep Groove or Spherical Roller

- Open/Sealed/Shielded

Bearings for Mining Industry Trade Information

- 10000 Per Week

- 3 Days

Product Description

Bearings for Mining Industry are widely demanded as per the clients requirements. We are a trusted trader of the same to our highly esteemed clients. They are obtained from our dependable vendors overseas. They make use of high grade material and machinery for their making as per the globally laid standards. Bearings for Mining Industry are tested at our unit prior to dispatch to make sure that no compromise is done with their quality at any stage. We offer these at economical prices.

Features:

- Unmatched Quality

- Feasible Prices

- Easy to Install

- Timely Delivery

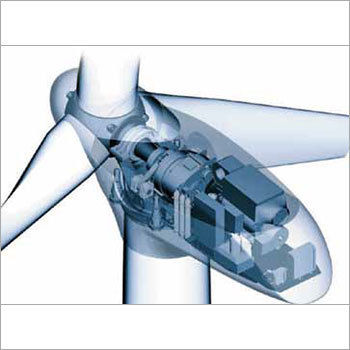

Engineered for Harsh Mining Environments

Our mining industry bearings are built to perform under the most challenging conditions, with robust construction that resists rust and corrosion and withstands high impact loads. Their advanced design ensures reliable operation in temperatures from -30C to +120C, making them ideally suited for mining equipment, crushers, and conveyors in demanding environments.

Versatile Designs and Customizable Solutions

Choose from deep groove, spherical roller, or tapered roller bearings in ball or roller types, with single or double rows. These bearings accommodate a wide range of bore sizes (30300 mm) and outside diameters (60400 mm), and are available in open, sealed, or shielded versions. Custom sizing is available to meet specific application needs, ensuring the perfect fit for every mining operation.

Extended Service Life and Easy Maintenance

With an extended service life and low noise level, these bearings offer reliable performance and reduce operational costs over time. Thanks to their easy-fit installation and options for grease or oil lubrication, maintenance is simplifiedkeeping mining operations running efficiently and minimizing downtime.

FAQs of Bearings for Mining Industry:

Q: How are these bearings suitable for harsh mining environments?

A: These bearings feature a rust and corrosion-resistant finish and are engineered to endure extreme temperatures ranging from -30C to +120C. Their enhanced shock load resistance and robust materials ensure reliable performance amidst heavy impacts and abrasive conditions typical in mining operations.Q: What types and sizes of bearings are available for mining applications?

A: A comprehensive range is offered, including deep groove, spherical roller, and tapered roller bearings. Sizes cover bore diameters from 30 mm to 300 mm and outside diameters from 60 mm to 400 mm, with thicknesses between 18 mm and 80 mm. Single or double row structures, as well as open, sealed, or shielded sealing options, are available to suit diverse requirements.Q: Where can these bearings be used in mining operations?

A: These bearings are ideal for use in various mining applications such as equipment, conveyors, and crushers. Their robust design makes them suitable for installation wherever heavy-duty load handling and resilient performance in harsh conditions are necessary.Q: What is the installation process and are custom sizes available?

A: The bearings are designed for easy-fit installation, minimizing downtime during setup or replacement. Custom sizing is also available to meet specific machinery or operational needs, ensuring an optimal fit and maximum efficiency in any mining setup.Q: How do these bearings contribute to extended service life and reduced maintenance?

A: Constructed from high-grade chrome or stainless steel, and available with steel, brass, or polyamide cages, these bearings offer superior wear resistance. Their high-precision rating (ABEC 15) and effective lubrication (grease or oil) options further contribute to long operational life and low maintenance requirements.Q: What are the benefits of choosing these bearings for mining industry supply chains in India?

A: Distributors, importers, suppliers, and wholesalers in India benefit from a reliable, durable product that minimizes equipment downtime and maintenance costs. The ability to order custom configurations ensures tailored solutions for diverse mining challenges, enhancing overall operational productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free