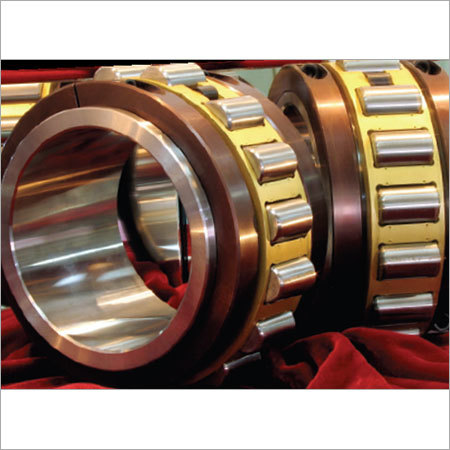

Split Bearings

Product Details:

- Precision Rating P6

- Lubrication Type Grease

- Thickness 30 mm

- Cage Material Steel

- Retainer Yes

- Inside Diameter 80 mm

- Bearing Type Split Bearing

- Click to View more

X

Split Bearings Price And Quantity

Split Bearings Product Specifications

- Steel

- 2200 RPM

- High

- Yes

- 140 mm

- Split Bearing

- Cast Iron Housing, Chrome Steel Bearing

- 80 mm

- P6

- Double Lip Seal

- Split

- Grease

- 80 mm

- Single Row

- 30 mm

Split Bearings Trade Information

- 10000 Per Week

- 3 Days

Product Description

Having core competency in this domain, we are instrumental in offering a wide range of Split Bearings. The main purpose of these bearings is to reduce rotational friction and support axial loads. The provided bearings are manufactured using quality examined metal alloy by skilled technical experts at highly developed production unit. In addition, these Split Bearings are made accessible to the patrons in varied specifications at market leading prices.

Features:

- Enhanced durability

- High tolerance

- Corrosion resistance

- Less maintenance

Reliable Performance in Tough Conditions

These split plummer block bearings feature a cast iron housing and chrome steel construction to withstand the rigorous demands of mining, conveyors, and heavy equipment operations. The painted or coated exterior resists corrosion, while the double lip seals offer enhanced protection against contamination for extended operational life.

Effortless Maintenance and Interchangeability

Their split structure design makes replacing the inner bearing simple and fast, significantly reducing downtime. Standard shaft size compatibility ensures easy replacement and interchangeability across most industrial setups, making these bearings highly versatile for distributors and service teams.

Optimized for Safety, Speed, and Efficiency

Designed to operate between -20C to 120C, these bearings deliver stable performance at speeds up to 2200 RPM with low noise and high shock resistance. Their robust construction supports demanding applications, while grease lubrication and steel cages maintain optimal running conditions.

FAQs of Split Bearings:

Q: How are split plummer block bearings installed and maintained?

A: Split plummer block bearings are designed for base mounting and their split construction allows easy installation and maintenance. The inner bearing can be replaced without removing the housing or shaft, reducing downtime significantly for conveyor, mining, or heavy machinery operations.Q: What are the main advantages of using split bearings with a double lip seal?

A: The double lip seal on these split bearings offers superior protection against contaminants like dust and moisture. This design choice prolongs bearing life and maintains low noise levels, especially in harsh environments common to mining and heavy equipment applications.Q: When should I choose a split plummer block bearing for my machinery?

A: Split plummer block bearings are ideal when easy maintenance and rapid bearing replacement are priorities. Their high static and dynamic load ratings, combined with their resistance to shock and corrosion, make them suitable for critical equipment in mining, conveyors, and other heavy-duty systems.Q: Where can these bearings be used most effectively?

A: These bearings are most effective in industrial scenarios such as mining equipment, heavy machinery, and conveyor systems. Their robust structure and interchangeable standard shaft fit make them suitable for a wide range of demanding installations in India.Q: What is the process for replacing a worn-out inner bearing in these split units?

A: To replace the inner bearing, simply disassemble the split housing, remove the old bearing, and insert the new one. The process is straightforward and does not require the dismounting of shafts or the entire housing, making on-site maintenance quick and efficient.Q: Can I use these bearings for high speed applications?

A: Yes, these bearings support limiting speeds up to 2200 RPM. Their precision rating of P6 and use of grease lubrication ensure smooth operation with low noise, making them suitable for applications requiring both speed and reliability.Q: What benefits do distributors and wholesalers in India gain from stocking these split plummer block bearings?

A: Distributors and wholesalers benefit from offering a product that is both versatile and in high demand for industrial maintenance. Its user-friendly design, robust construction, and compatibility with standard shaft sizes make it a reliable choice for a broad customer base in India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free