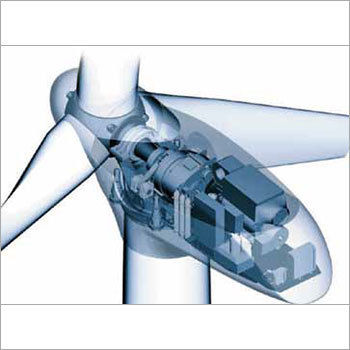

Turbine Bearings

Product Details:

- Precision Rating P5 / P6 / P4

- Retainer Solid

- Lubrication Type Grease / Oil

- Inside Diameter Up to 150 mm

- Thickness Standard/Custom

- Cage Material Brass / Steel / Polyamide

- Bearing Type Turbine Bearing

- Click to View more

X

Turbine Bearings Price And Quantity

Turbine Bearings Product Specifications

- Up to 11,000 RPM

- Turbine Bearing

- Alloy Steel / Stainless Steel

- Spherical

- High

- Open / Sealed

- Customizable as per application

- P5 / P6 / P4

- Single

- Solid

- Grease / Oil

- Up to 250 mm

- Up to 150 mm

- Standard/Custom

- Brass / Steel / Polyamide

Turbine Bearings Trade Information

- 10000 Per Week

- 3 Days

Product Description

Over the years of dedication, we have been a prominent trader of Turbine Bearings to our huge clientele base. They are used at different places to meet their diverse requirements. Supreme quality material is employed for their fabrication along with the help of progressive machinery at our vendors unit. Turbine Bearings are inspected on various parameters to make sure that no compromise is done with their quality at any stage. We offer these at highly affordable prices in the market.

Features:

- Fine Finishing

- Durable Quality

- Easy Installation

- Long Life

Precision Engineering for Turbine Performance

Our turbine bearings are meticulously crafted to ensure smooth, high-speed rotation and minimal vibration, making them ideal for steam, gas, and hydro turbines. The use of quality alloy or stainless steel enhances durability and corrosion resistance, ensuring long-term reliability even under extreme mechanical stress. Each bearing is finished to a polished standard for smoother operation and reduced wear.

Versatile Customization for Diverse Applications

We offer a broad range of customization options, allowing for tailored bore sizes, thickness, and cage materials to suit your specific turbine requirements. Whether you need open or sealed bearings, single-row configurations, or high-precision ratings, our solutions adapt seamlessly to your operational goals. This flexibility ensures that every bearing matches the exact demands of your machinery.

Distributor, Importer & Supplier in India

As a trusted distributor, importer, and supplier of turbine bearings across India, we provide comprehensive support and rapid delivery to power plants, OEMs, and industrial sectors. Our team assists with selection, technical consultation, and after-sales service, ensuring our customers receive bearings suited to their unique challenges and operational environments.

FAQs of Turbine Bearings:

Q: How are turbine bearings designed to handle high speeds and low vibration?

A: Turbine bearings are engineered with precise tolerances, spherical structures, and options for solid retainers and specialized cage materials like brass or polyamide. These features enable stable rotation at speeds up to 11,000 RPM while minimizing vibration and maintaining structural integrity.Q: What makes these bearings suitable for steam, gas, and hydro turbines?

A: These bearings are constructed from robust materials such as alloy steel or stainless steel, which resist corrosion and thermal stress within -30C to 200C. The high load capacity and enhanced durability enable them to perform reliably in diverse turbine environments.Q: When should turbine bearing customization be considered?

A: Customization is recommended when specific operational requirementssuch as non-standard bore sizes, unique sealing types, or higher precision gradesare needed to optimize performance in unique turbine applications. Our team can tailor these aspects to customer specifications.Q: Where can these turbine bearings be sourced in India?

A: We supply, distribute, and import turbine bearings throughout India, directly serving power plants, OEM manufacturers, and maintenance sectors. Customers can contact us for consultation, supply, and technical support for all turbine bearing needs.Q: What is the process for selecting the right bearing type for a turbine?

A: Selecting the right bearing begins with assessing operational parameters such as load ratings, speed, temperature range, and the intended turbine type. Our experts guide customers through this process, ensuring an ideal match based on the required specifications.Q: How does enhanced corrosion resistance benefit turbine bearing usage?

A: Enhanced corrosion resistance protects the bearing from premature degradation in harsh environments, extending service life and reducing the frequency of maintenance or replacement. This is especially valuable in applications exposed to moisture or high temperatures.Q: What are the key benefits of using polished turbine bearings with high-precision ratings?

A: Polished finishes and high-precision ratings (P4, P5, P6) reduce friction, ensure smoother movement, and enhance the lifespan of the bearing. These factors contribute to greater overall efficiency and reliability of the turbine system.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free