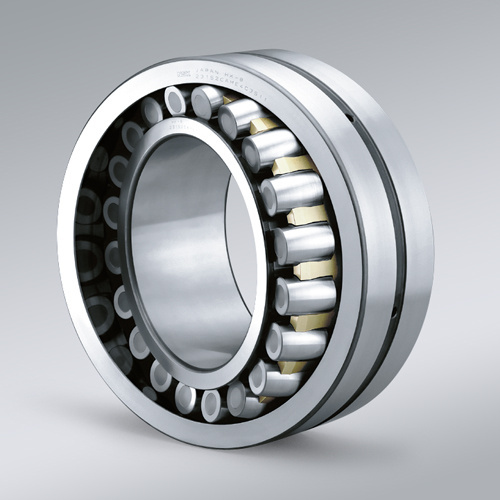

Vibrating Equipment Bearings

Product Details:

- Lubrication Type Grease/Oil

- Cage Material Brass

- Thickness 19 mm

- Retainer Pressed Steel

- Precision Rating P5

- Inside Diameter 30 mm

- Bearing Type Vibrating Equipment Bearing

- Click to View more

X

Vibrating Equipment Bearings Price And Quantity

- 10000 Piece

Vibrating Equipment Bearings Product Specifications

- 30 mm

- Vibrating Equipment Bearing

- Chrome steel

- Open / Sealed

- 30 mm

- Grease/Oil

- 72 mm

- Pressed Steel

- 19 mm

- Spherical Roller Bearing

- Brass

- High (Heavy Duty)

- 2300 RPM

- Double Row

- P5

Vibrating Equipment Bearings Trade Information

- 10000 Piece Per Week

- 3 Days

Product Description

Being a quality focused firm, we are successfully meeting the demands of our patrons by offering pristine quality Vibrating Equipment Bearings. These bearings are manufactured by utilizing quality examined metal alloy at advanced production house by adept experts. The provided bearings are well suited for supporting axial and radial loads in diverse vibrating machines & equipment. Moreover, we are offering these Vibrating Equipment Bearings in bulk to the patrons.

Features:

- Accurate dimension

- Easy to fit

- Sturdiness

- Non corrosive

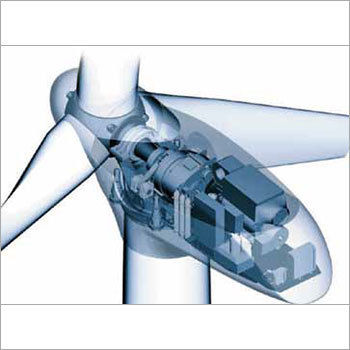

Engineered for Demanding Applications

Specifically designed for vibrating screens and mining machinery, these bearings offer exceptional load capacity and reliability. The spherical roller structure, double-row configuration, and high precision rating make them suitable for the most rigorous industrial conditions, providing an optimal solution for continuous heavy-duty usage.

Performance and Reliability

With dynamic load ratings of 110 kN and static load ratings of 92 kN, these bearings support high-impact operations with ease. The through-hardened chrome steel and precision manufacturing ensure long service life, even under substantial stress and rapid vibrations. The brass cage and pressed steel retainer further enhance bearing stability.

Certified Quality for Industrial Needs

Each bearing is manufactured under ISO 9001:2015 certification, ensuring stringent quality control from start to finish. The open or sealed options, grease or oil lubrication compatibility, and polished surface finish guarantee versatile performance across various manufacturing and industrial scenarios.

FAQs of Vibrating Equipment Bearings:

Q: How should Vibrating Equipment Bearings be installed in mining machinery or vibrating screens?

A: To install these bearings, ensure the housing and shaft are clean and properly dimensioned. Position the bearing carefully, aligning the bore and outside diameter (30 mm and 72 mm, respectively), and use the appropriate mounting tools to avoid damage. Always refer to the manufacturers guidelines for best practices.Q: What applications are best suited for these double-row spherical roller bearings?

A: These bearings are optimal for vibrating screens, mining machinery, and other heavy-duty industrial equipment where high load capacity and vibration resistance are essential. The robust design and ability to perform under dynamic loads make them particularly effective in rigorous mining and quarrying operations.Q: When should these bearings be serviced or replaced?

A: Regular inspection is recommended, especially in harsh conditions. Service intervals depend on factors such as load intensity, operating temperature, and lubrication quality. Indications for replacement include increased noise, excessive vibration, or visible surface damage. Following a scheduled maintenance routine ensures optimal performance and longevity.Q: Where are these vibrating equipment bearings typically distributed or supplied in India?

A: These bearings are distributed, imported, and supplied throughout India by authorized wholesalers and distributors specializing in industrial machinery parts, particularly those serving the mining and construction sectors.Q: What is the process for lubricating these spherical roller bearings?

A: Lubrication can be performed using either grease or oil, depending on operating conditions and manufacturer recommendations. Ensure the bearing is equipped with the correct seals (open/sealed options available) and that the lubricant is compatible with both the bearing material and operating temperature range (-30C to +150C).Q: How does the bearings precision rating and material benefit heavy-duty applications?

A: A P5 precision rating ensures minimal dimensional variance, allowing for consistent, smooth operation at high speeds and under heavy loads. The chrome steel construction and through-hardened heat treatment offer excellent resistance to wear and fatigue, which is crucial for continuous operation in demanding environments.Q: What packaging ensures the safety and quality of these bearings during transport?

A: Each bearing is shipped in a sturdy corrugated box, providing protection against moisture, dust, and mechanical damage during transit. This packaging, combined with strict quality control protocols, maintains the integrity and performance of the bearing upon delivery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Bearings' category

|

VELY INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free